Green hydrogen

Why hydrogen is the fuel of the future

As 47% of the world’s industries aren’t compatible with electrification, we will need viable alternatives to fully move away from fossil fuels. Clean hydrogen will be one of them. In fact, the growing demand for green and blue hydrogen means that it could represent over 20% of the world’s energy demand by 2050.

Hydrogen is a suitable energy carrier and feedstock for many applications, especially in the hard-to-abate sectors. So, providing that it comes from renewable and low-carbon sources, this could be a vital component on the road to net-zero. We can already see the key role that hydrogen, and its derivatives, will play in several industries, like chemical and steel production. It can also be used as fuel in marine and on/off road transportation sectors, as well as providing flexible power generation.

How clean hydrogen is produced

Green, or clean, hydrogen is produced using an electrolyser, where renewable electricity splits water molecules into hydrogen and oxygen.

Whether you are using PEM, Alkaline or Solid Oxide electrolyser technology, Alfa Laval has an energy efficient and scalable solution for you. Our heat transfer technology can support you with everything from cooling electrolytes and gases, to recovering excess heat, and balancing of the plant.

On top of that, our freshwater generation technologies make it possible for our customers to reuse the excess heat from their electrolyser, while also converting sea or river water into the pure water needed for these applications.

Green hydrogen gives hope for the future

Green hydrogen has long held promise for achieving Europe’s climate targets. Now in Germany, a new pilot project is showing the potential to make this a reality. Using Alfa Laval heat exchangers, Thyssenkrupp Uhde Chlorine Engineers GmbH is testing hydrogen instead of injection coal to reduce CO2 emissions in ongoing blast furnace operations at its Duisburg site. The only thing left over from this new process is water vapor.

This project, which is funded by the German government, uses the metallurgical gases produced during steelmaking to produce chemicals, thus reducing CO2 emissions in both steelmaking and chemical production. Check out the full story to learn more about the critical role Alfa Laval technology has played in this pilot.

Our solutions

Alfa Laval gasketed plate-and-frame heat exchangers

Alfa Laval’s extensive portfolio of gasketed plate-and-frame heat exchangers are the ideal choice for the electrolyser in any green hydrogen plant. With their small footprint and high efficiency, our gasketed plate heat exchangers offer a great solution for modularized plants and can simultaneously be expanded to meet future needs. The best-in-class heat transfer capabilities minimize payback time for your heat integration projects. Available in a wide range of materials including iron-free solutions like nickel, these heat exchangers help you to ensure reliable operation throughout the lifetime of the electrolyser.

Alfa Laval printed circuit heat exchangers

Alfa Laval printed circuit heat exchangers offer years of proven performance, combining superior robustness and integrity with an exceptionally high heat transfer rate – all in a unit that’s up to 85% smaller and lighter than comparable shell-and-tube heat exchangers. The durable designs handle pressures up to 1,250 barg (18,125 psig) and temperatures ranging from deep cryogenic duties to very high temperatures. Our unique anti-freezing technology opens up use across the whole hydrogen distribution refuelling station energy chain – from liquid H2 to gas.

Alfa Laval freshwater generators

Alfa Laval freshwater generators (FWG) can provide the best solution for delivering water in the right quality for the electrolysis process, enhancing the lifetime of the electrolyser. The titanium plates ensures high uptime and reliability for the desalination the process. With more than 30,000 units delivered over 60 years in the offshore and marine industries, they ensure reliable operation within the smallest footprint in centralized and decentralized systems for green hydrogen production.

Alfa Laval Zero Liquid Discharge

Alfa Laval ZLD systems are robust, compact solutions designed for the absolute minimization of liquid discharge in a wide range of applications including underground caverns. ZLD systems separate out salt and enable water reuse for injection. via a combination of thermal solutions and separation technology, with the AlfaFlash evaporator at the core of the set up.

Alfa Laval Niagara Wet Surface Air Coolers (WSAC)

Wet Surface Air Coolers (WSAC®) are a perfect fit for all cooling needs in hydrogen compression and transport. They are custom-built, closed-loop evaporative cooling and condensing systems. By direct cooling of the process fluid, a WSAC system can reach lower temperatures and is more compact than any alternative air cooler technology. And since no high-quality fresh water is required, with low-quality waste water instead used as cooling medium, they also offer a very sustainable solution.

Alfa Laval fusion bonded plate exchangers

Our patented AlfaFusion bonding technology creates highly efficient, compact heat exchangers made entirely of stainless steel. Virtually maintenance free and capable of handling high pressures and temperatures, they are an ideal heat transfer solution for challenging applications, including those with temperatures approaching 600°C.

Heat transfer solutions for Fuel cells

Fuel cells are going to be one of the fundamental pieces in solving our energy transition puzzle. Looking for information on polymer electrolyte membranes (PEM), solid oxide fuel cells (SOFC) or fuel cell solutions for stationary applications? With our extensive experience in thermal technology, Alfa Laval can help you meet the demands of challenging applications.

Heat transfer solutions for power-to-X

Power-to-X involves the conversion of electricity into gaseous and liquid fuels or chemicals, including e-ammonia, e-methanol, methane, green hydrogen and syngas. In this way, it can enable decarbonization for industry, transportation and energy, as well as provide an important energy storage solution. With decades of experience providing solutions to the chemical industry, Alfa Laval can support power-to-X duties with a diverse portfolio of efficient heat exchangers.

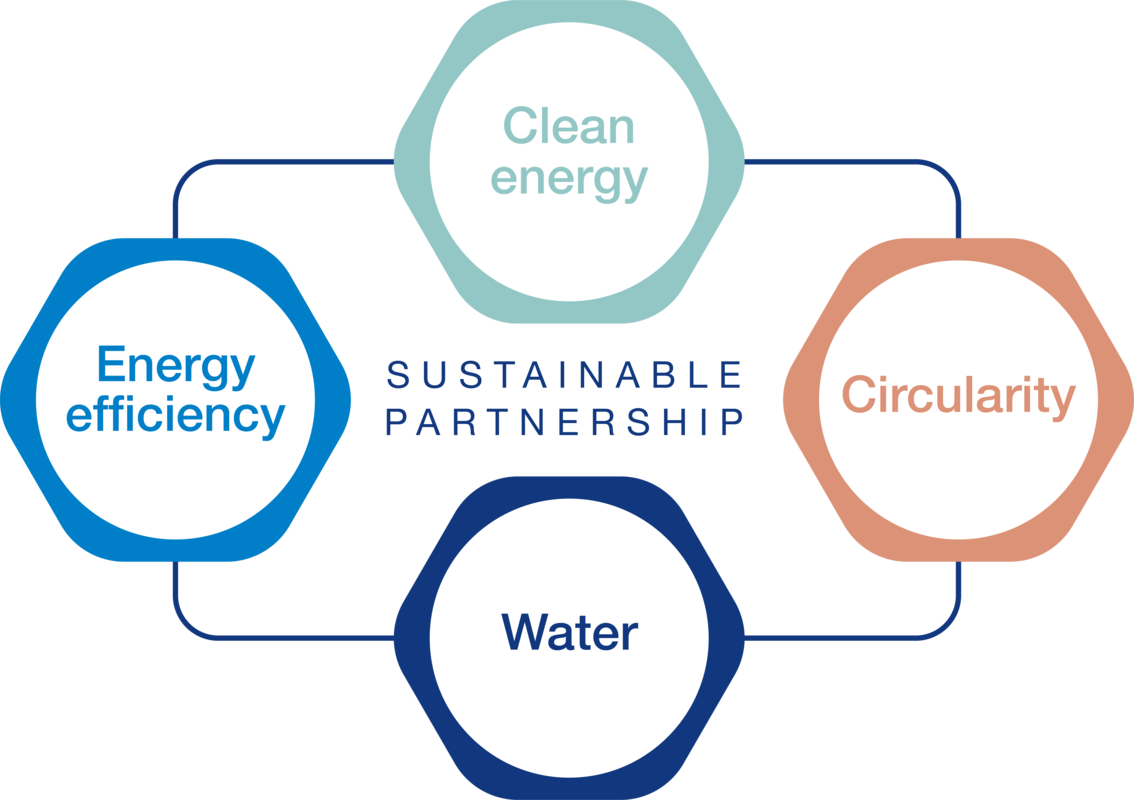

Energy efficiency

Clean energy

Sustainable partnership

Contact us to learn more

Contact us today for more information about our sustainable solutions