Niagara Wet Surface Air Coolers

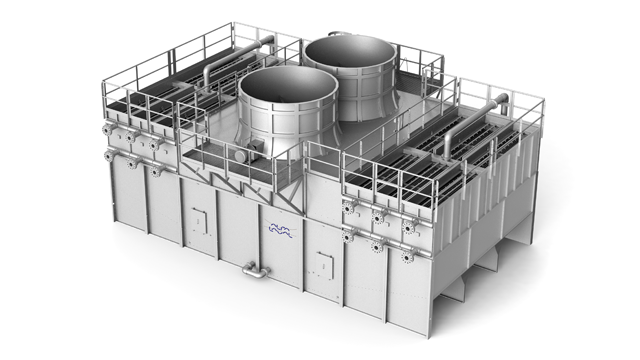

Alfa Laval Niagara Wet Surface Air Coolers (WSAC®) are custom built, closed-loop cooling and condensing systems that combine high performance, low operating costs, compact size and reliable operation. Renowned for their robust design and high efficiency, Alfa Laval Niagara WSACs are used in a large number of demanding industries. Their low water consumption and high cooling capacity have made them a popular choice in applications where low temperatures are required for process improvements.

Benefits

- Lowest possible process fluid outlet temperature thanks to evaporative cooling

- Minimal water consumption – cooling water can be re-circulated and the makeup water can be of low quality

- Low energy consumption

- Compact size and lowest lifecycle cost

- Well-proven technology and long service life

Meet our experts

Full cooling capacity cooling systems all year round

The sustainable alternative to cooling tower systems & air coolers

Effective and efficient cooling

Minimize life cycle cost & maximize cooling performance

Improving sustainability with welded solutions from Alfa Laval

Alfa Laval welded heat exchangers maximize energy efficiency and heat recovery, with innovations that deliver exceptional thermal performance and reliability, for a wide range of duties. But it’s more than technology. It’s also the people: experienced experts with deep process knowledge and a global service presence. Combined, that’s how you improve sustainability.

Fully customized

Highly durable equipment

Alfa Laval WSACs are engineered to meet heavy-duty industrial requirements and standards. They can sustain pressures up to 2500 psi and be designed to meet ASME, TEMA, PED and API specifications. All materials in contact with the process stream can have full ASME material certification if required. The units are fireproof and can be constructed for use in Ex environments.

The tubes can be either straight or serpentine shaped. Straight tubes are the preferred choice for fouling process media and when a low pressure drop is required. The piping can be arranged and valved so that any tube bundle can be taken out of service for maintenance while the unit is in operation.

As standard, all components are made of hot-dip galvanized steel with excellent resistance to corrosion. For applications with corrosive media, the tube bundles can be delivered in a variety of materials, for example different grades of stainless steel, super duplex and titanium.

Engineered-to-order systems

All Alfa Laval WSAC systems are unique and custom designed to fit the exact requirements of their intended duties. This includes inlet and outlet temperatures, ambient conditions, flow rate, presence of corrosive media, required pressure drop, etc.

Redundancy can be built into the units in order to minimize or eliminate downtime for maintenance. This can include components such as spare fans, spray pumps and even tube bundles. The units can also be designed to cool several separate process streams independently.

From small to large

WSAC systems come in all sizes from small, packaged units to large field-erected systems:

Packaged systems

The packaged systems are skidded, pre-piped and pre-wired units, complete with control cabinets. These factory-tested, plug-and-play units ensure a fast and easy installation, and keep the associated installation costs low.

Modular systems

Our modular systems are ideal where cooling capacity needs to be expanded simply and efficiently. These medium sized WSACs have casings made of heavy-gauge steel and are delivered in pre-fabricated modules that are easily assembled on site.

Field-erected WSAC systems

Our largest systems are field erected. The basin is made of concrete and the overlying structure can be made of either fibre reinforced plastics (FRP) or concrete. A field-erected system is comprised of custom-designed tube bundles, which provide optimum maintainability over the lifetime of the system. A field-erected WSAC system offers the lowest total cost of ownership for duties where high-capacity cooling/condensing is required.

Comparison with other technologies

WSAC systems produce the coldest possible process outlet temperature compared to other technologies.

Other WSAC advantages are shown in the following table.

In this example the air temperatures are:

Dry bulb T = 37.7°C (100°F)

Wet bulb T = 26.1°C (79°F)

| Wet Surface Air Cooler (WSAC) | Cooling tower plus heat exchanger | Traditional air-cooled heat exchanger (dry) | |

| Practical approach temperature | 5.6°C (10°F) | 8.3°C (15°F) in total, 5.6°C (10°F) for CT and 2.7°C (5°F) for heat exchanger | 8.3°C (15°F) |

| Coldest practical process temperature | 31.7°C (89°F) | 34.4°C (94°F) | 46.1°C (115°F) |

| Water consumption | Low-medium | High | Not applicable |

| Electrical consumption | Low | Medium | High |

| Space requirements | Small | Medium-large | Large |

| Total system cost | Low-medium | Medium | Medium-high |

| Maintenance | Low-medium | Medium-high | Low |

Sustainable performance

Optimizing your cooling processes is a straightforward way to improve sustainability – both in business and environmental terms. With the right equipment you maximize cooling performance and energy efficiency, while keeping water consumption and service costs low. Check out our brochure to find out how we can help you improve your cooling operations.

How it works

An Alfa Laval WSAC can be used for liquid and gas cooling, as well as condensing duties.

The WetSurface technology used in a WSAC system is based on evaporative cooling. The hot process medium flows through prime surface tube bundles that are sprayed with water. The heat causes the water to evaporate and the vapour is removed by fans that draw cool air over the tubes.

The water that does not evaporate is collected in a basin and is reused as spray water. The same cooling water can be reused 6-10 times, depending on water quality.

Next, the air/water vapour stream is forced to make a 180° turn, which effectively removes free water droplets and minimizes drift.

An Alfa Laval WSAC is a closed loop system, meaning there is no risk of contaminants entering the process stream.

Temperature limitations

For liquid cooling the maximum inlet temperature is 82°C (180°F).

For single phase gas cooling the maximum inlet temperature is 232°C (450°F).

For vapour condensing the maximum inlet temperature is 82°C (180°F).

Extreme environments

Limited water resources made a Middle East refinery use Red Sea water for its cooling needs. The large salt content of sea water causes high fouling and corrosion, generally making it extremely difficult for cooling.

Improved efficiency

A gas processor in Texas, U.S. wanted to improve efficiency of the NGL fractionator process while reducing operating costs and increasing NGL production. Learn how the Wet Surface Air Cooler offered the perfect solution.

Less water consumption

The Chuck Lenzie Generating Station, a combined cycle power plant in Nevada, was challenged to cool the closed loop auxiliary water while conserving make-up water based on allowed annual limitations of water availability.

Unique features

Contact us

We will be happy to discuss the benefits an Alfa Laval Wet Surface Air Cooler can bring you and show you how we can help improve your operation.

Get the latest news on LinkedIn

Stay tuned to our LinkedIn page for the latest news on Alfa Laval Wet Surface Air Coolers.