Carbon capture, utilization and storage

Carbon capture and storage (CCS) is an essential piece of the puzzle when it comes to reaching net zero. In fact, according to the IEA, we will need to increase our global carbon capture capacity to 1.6Gt CO2 by 2030 and continue raising it to 7.6Gt CO2 by 2050, if we are going to reach our goals on time.

That is why Alfa Laval is pioneering innovative solutions for more thermally efficient carbon capture, combining tried and true technology with brand new solutions. In fact, our broad portfolio of solutions can already reduce energy consumption in a CCS plant by up to 40%.

Accelerating cost-effective carbon capture

Alfa Laval heat exchanger technology has played a central part in over half of the world’s CCU/S plants. Our unique Alfa Laval Packinox plate-and-frame heat exchangers are enabling the development of sites that will facilitate the possibilities of carbon capture at large economies of scale. Read this story to learn more about the role heat transfer plays in carbon capture and how we are working with major process licensors and end-users to make it possible.

Our solutions

Alfa Laval has a broad portfolio of heat exchangers to meet the energy-intensive demands of CCU/S applications. We can help you maximize energy recovery in a range of duties, including for lean/rich interchangers, the largest heat recovery duty in the process. We also offer solutions for minimizing energy and cooling water needs, while maximizing CO2 capture efficiency and reducing the cost for the compressor package and other process equipment.

Alfa Laval WideGap

WideGap gasketed plate-and-frame heat exchangers are tailor-made for low pressure condensation, taking advantage of a larger than normal channel gap to minimize pressure drop on the condensing side. Its unique design makes it possible to maximize condensing with the lowest possible amount of vapour going to the compressor. This reduces investment cost and power consumption in the compressor package. WideGap is therefore well suited to the specific stripper condensation services in carbon capture processes.

Alfa Laval Compabloc welded heat exchanger

With over 30,000 units handling tough duties worldwide, Compabloc is the market champion when it comes to heat transfer. Its compact design has been engineered for superior reliability and performance, making it easy to both service and install. Plus, our Compabloc family is 3-5 times more efficient than traditional shell-and-tube solutions and secures safe operation of up to 60 bar. Learn more about our range to find out how we have improved our process sustainability with you in mind.

Alfa Laval Packinox plate-and-frame heat exchanger

An Alfa Laval Packinox plate-and-frame heat exchanger is the perfect choice for heat transfer duties in processes with large flows, high temperatures and high pressures. Its superior thermal performance lets you increase energy efficiency, grow profitability and minimize your environmental impact. A single Packinox heat exchanger outperforms systems consisting of multiple large shell-and-tubes, both in terms of heat recovery and investment costs.

Alfa Laval gasketed plate-and-frame heat exchangers

Our industrial line of gasketed plate heat exchangers is suitable for duties where high, cost-efficient heat recovery is required. They are also excellent for reducing cooling water consumption. With a design for long operation and minimal maintenance requirements, they set all new standards of efficiency, reliability and serviceability.

Alfa Laval Niagara Wet Surface Air Coolers

Niagara Wet Surface Air Coolers (WSAC®) are custom-built, closed-loop cooling and condensing systems that combine high performance, low operating costs, a compact size and reliable operation. Using air as the cooling media minimizes process outlet temperatures, which further minimizes the amount of vapour going to the compressor stage, while keeping it at a higher density. This ensures a low investment cost in the compressor package.

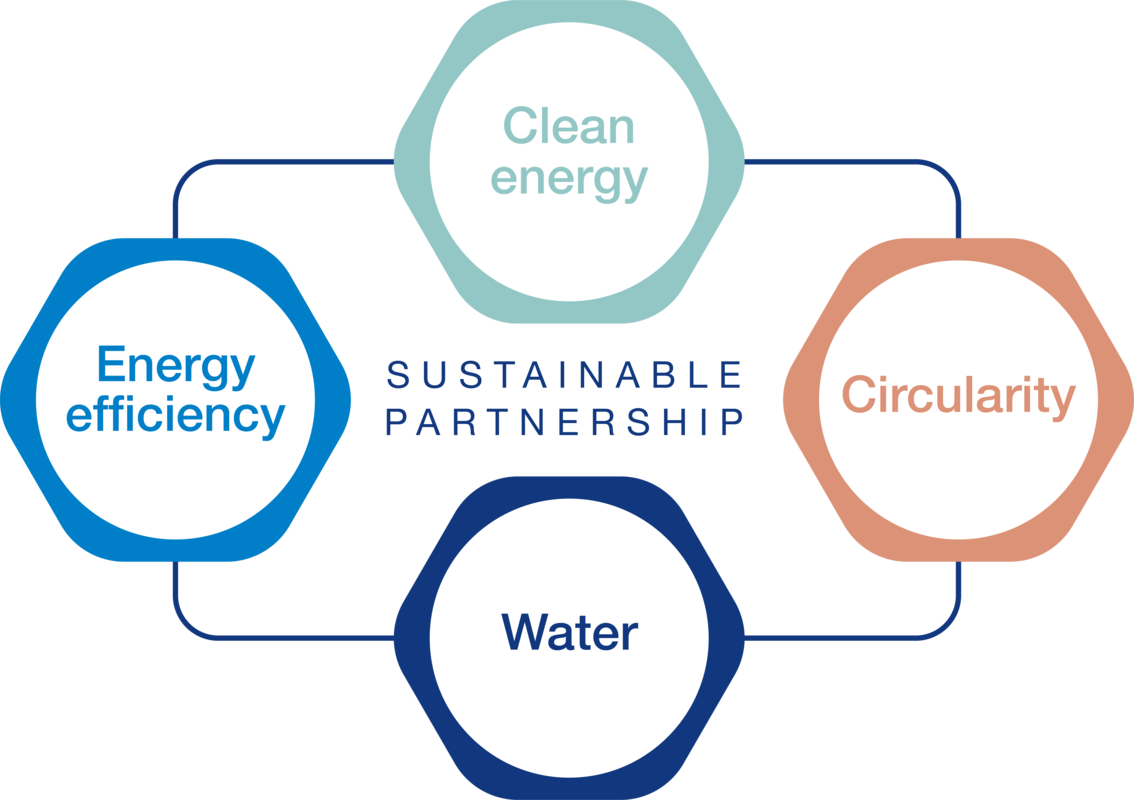

Energy efficiency

Clean energy

Sustainable partnership

Contact us to learn more

Contact us today for more information about our sustainable solutions