A new top-of-the-line in beer separation

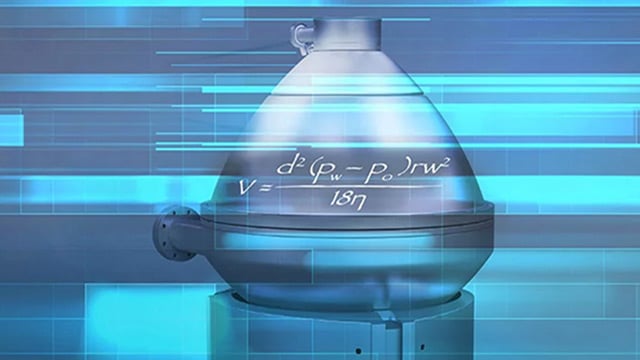

With the new Alfa Laval Brew 450 and 750 brewery centrifuges, we have taken our already leading disc stack technology to even higher levels of performance. Built with Alfa Laval’s unique, bottom-fed hermetic design, they deliver an unmatched combination of efficient separation and energy savings, while enhancing the flavour and aroma of your beer. That translates to new potential for your brewery to boost yield and product quality as you simultaneously minimize operational costs. There’s a reason we’re proud to call these centrifuges the new top-of-the-line.

A new top-of-the-line in beer separation

The latest additions to the Alfa Laval Brew family of centrifuges take the leading disc stack technology to the next level. Built with our unique, bottom-fed hermetic design, they deliver an unmatched combination of efficient separation and energy savings. That means increased yield and product quality together with enhanced flavour and aroma possibilities. There’s a reason we’re proud to call these the new top-of-the-line.

Brew 250

- Polisher for small-sized craft brewers

- Capacities up to 140 hl/h

- Bottom-fed, fully hermetic design ensures zero oxygen pickup and low power consumption

- Simple to operate with low maintenance costs

- Plug-and-play skid for fast, easy installation

Brew 450

- Centrifuge for pre-clarification and polishing duties in mid-size breweries

- Capacities up to 500 hl/h

- Bottom-fed, fully hermetic design ensures zero oxygen pickup and low power consumption

- Easy-to-install modularized system

- Simple to operate with low maintenance costs

Brew 750

- Centrifuge for pre-clarification and polishing duties in large breweries

- Capacities up to 1000 hl/h

- Bottom-fed, fully hermetic design ensures zero oxygen pickup and low power consumption

- Easy-to-install modularized system

- Simple to operate with low maintenance costs

Brew 750e

- Centrifuge for pre-clarification and polishing duties in large breweries

- Capacities up to 1000 hl/h

- Bottom-fed, fully hermetic design ensures zero oxygen pickup and low power consumption

- Maximum energy efficiency thanks to eDrive™ direct drive system and eMotion™ friction-reducing design

- Easy-to-install modularized system

You can see the complete range of Alfa Laval Brew centrifuges here.

Hermetic design: superior beer, supreme savings

Only Alfa Laval offers fully hermetic, bottom-fed centrifuges for breweries. The benefits of this unique design are many:

- Zero risk of dissolved oxygen pick-up

- Improved flavour and aroma characteristics

- Superior head retention

- Increased energy efficiency

- Reduced maintenance needs

Find out how hermetic technology can improve your beer – and your bottom line.

eMotion + eDrive = the market’s lowest energy consumption

Available on our new Brew 750e centrifuge, the eMotion™ feature reduces air pressure and friction in the space between the centrifuge’s rotating bowl and frame. Combined with the eDrive™ direct-drive motor system, the design of eMotion™ thereby enables energy savings of up to 75% compared to traditional brewery separators. And lower power consumption is just the start. With eMotion™, frame temperatures stay below 30°C (86°F), offering an improved working environment and making CIP cleaning easier.

Is your brewery ready to discover the best of the best in separation innovation?

“Our beer went from good to exceptional…”

Hear from Adam DeBower, owner and founder of Austin Beerworks, about how a fully hermetic Alfa Laval centrifuge improved his brewery’s operations – and their beer. Thanks to the unique design and advanced features, along with first-class support from Alfa Laval’s leading brewery separation experts, his team has been able to take their craft beer from good to exceptional.

Ready to make your great beer even better? Contact us to find out which Brew model is right for you.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.

Local support and service for your centrifuge / high speed separator

Whether your application requires solids removal, clarifying, purifying, or polishing – continuous, high-speed centrifugal separation is a demanding process. And centrifuge maintenance isn’t always planned, which is why you’ll find an Alfa Laval service centre located in Hamilton to ensure rapid service, with the level of expertise you expect with Alfa Laval – all while minimizing downtime.