Edible oil refining process systems

Refining crude oil into edible oil requires deep process knowledge—from degumming, neutralization and dewaxing through to bleaching, deodorizing and GE and 3-MCPD mitigation. Edible oil producers worldwide rely on Alfa Laval know-how to remove impurities and volatile components and optimize refining processes. Count on us to ensure optimal taste, aroma, stability, appearance and nutritional value of your edible oils while maximizing product quality, safety and yield.

Highly reliable, versatile, easy-to-operate systems for quality edible oils

- Broad range of robust, reliable and easy-to-operate components, equipment and systems for edible oil processing

- Knowledge and practical expertise to incorporate equipment into applications and innovative solutions

- Vast experience in edible oil processing system design, installation, commission, service and support

- High product quality and yield, low product loss and utility consumption

Webinars for the Edible Oil industry

Our experts share know-how to optimize edible oil refining processes, remove impurities and volatile components for better product quality, safety and yield.

Get the most out of your crude oil with time-tested edible oil refining process solutions that optimize quality, ensure food safety and maximize yield

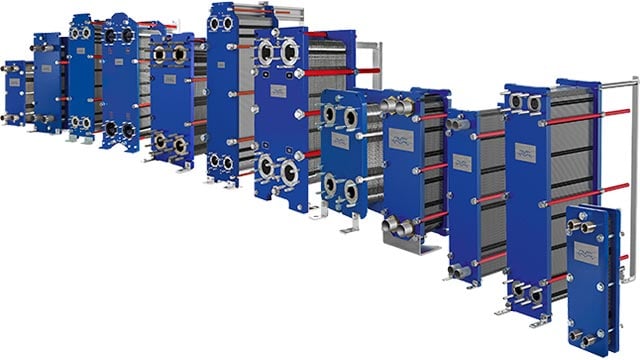

Alfa Laval holds more than 3700 patents, of which some 140 are specifically for edible oil systems. We continuously invest in R&D to enhance core components and equipment with innovative technology that optimizes our customers processes.

Whether you need complete systems to refine for edible oils or components and equipment to upgrade your existing process lines, you can rest assured we have your back. What you get is optimal design, reliability, ease of use, higher product quality, lower product losses and costs, minimized waste, global expertise and local service. All of which contribute to higher earnings and lower lifecycle costs.

Service and support optimize edible oil refining process systems

More than 130 years of experience. Experts the world over. Service centres in nearly 100 countries. For true peace of mind, take advantage of the Alfa Laval global service network with its solid local presence to maximize quality, efficiency and yield of your processes. No other process system supplier can provide the depth, breadth and range of components, equipment, systems and service. We’re always nearby, caring for your systems and optimizing your processes over the entire life cycle of your edible oil refining plant. Our edible oil systems can also be adapted for use in biodiesel and hydrotreated vegetable oil pre-treatment.

References

- More than 500 refineries (with neutralization/degumming, bleaching, deodorization)

- More than 140 dewaxing plants

- More than 75 dry fractionation plants

- More than 50 hydrogenation plants

- More than 30 interesterification plants

Publications

See an extensive list of peer-reviewed publications by Alfa Laval's experienced experts.

Our edible oil production line portfolio

After oil clarification (for pressed oils), the oil can be refined as shown below.

The crude oil is then transferred either to special degumming in the physical refining route, to water degumming, or directly to neutralization in the chemical refining route. In the chemical refining route, free fatty acids undergo a reaction to create aqueous soap, which is removed from the oil in centrifuges. The physical refining route removes only some impurities (mostly phosphatides, also known as phospholipids or gums) from the oil. Some oils, such as sunflower and corn, go through a dewaxing step to achieve the prescribed cold stability, that is, to be able to retain clarity at low temperature. The bleaching process removes additional impurities, such as metals, soap residues and colour components. Finally, to prolong shelf life, the oil undergoes deodorization to initiate thermal decomposition of residual colour, any components lending unwanted taste, and peroxides. Volatile compounds (mostly fatty acids) are removed via steam stripping at about 240 – 260°C under vacuum. Fatty acid distillate is produced as a valuable by-product in the physical refining route, much less so for the chemical refining route.

Last but not least, take advantage of our Utility Process Systems to further cut operational costs in your edible oil refining process by reducing utility expenses – whether power, process water, steam, fuel and/or cooling media.