Looking to the future in New Zealand waste water treatment

Alfa Laval belt thickeners help build wastewater treatment capacity in New Zealand.

DATE 2023-11-28

Auckland is the largest city in New Zealand, with a population of about 1.57 million in 2016 – about one-third of New Zealand's total population.

The city’s water supply and waste water disposal needs are dealt with by Watercare Service Ltd., New Zealand’s largest water utility and wholly owned by Auckland Council. In 2018, the company supplied about 365 million litres of water to Auckland every day, and collected, treated and disposed of about 460 million litres of municipal and industrial waste water daily.

Infrastructure growth

Auckland’s population has been growing constantly, and Watercare Service has repeatedly had to extend and upgrade its facilities. According to projections from Statistics New Zealand in 2017, Auckland's population could almost double in the next 25 years. This is one of the reasons why Watercare is planning to spend NZD 4.9 billion on infrastructure projects over the next ten years to provide additional capacity for dealing with the needs of Auckland residents and businesses.

One of the many facilities operated by Watercare Service is the Mangere Resource Recovery Facility. In 2015, the company wanted to upgrade and extend the plant’s solids stream thickening capacity, with considerable focus on environmental impacts, which is a major focus in Watercare Service operations and planning. For Watercare Service engineers, there was also particular focus on safety, energy efficiency and to deliver a reliable plant with low operations and maintenance input.

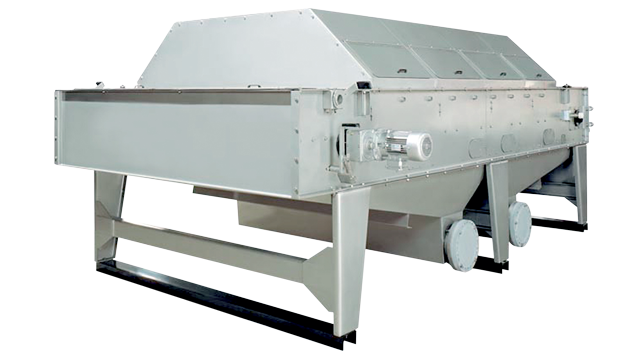

Alfa Laval Oceania won the tender for this project, covering the delivery, installation and commissioning of seven Alfa Laval AS-H 300 Belt Thickener units, which separate liquid from solids by gravity drainage through a 3-metre-wide porous filter belt. The new thickeners were configured to process waste activated sludge (WAS) and Three-Phase Separator (TPS) sludge.

Technical benefits

Watercare Service was particularly interested in the technical benefits of the Alfa Laval belt thickener design, in which sludge ploughs force the sludge into lanes so that free water runs unhindered through the filter belt where sludge is not present, making the thickening process more efficient. The ramp feature means the flow of thickened solids can be accurately adjusted and fine-tuned during operation.

They are also equipped with a sludge polymer mixing valve that makes sure polymer is thoroughly and consistently mixed into the sludge.

This was Alfa Laval’s first major order for belt thickener separation technology in New Zealand. According to Paul Doherty, Watercare Service Project Engineer at the Mangere WWTP and responsible for the solids stream upgrade, the equipment has exceeded his expectations regarding treatment capacity and reliability.

Bigger picture

But any technical benefits of Alfa Laval belt thickeners are really only part of a larger picture. As Watercare Service’s Paul Doherty points out, there have been significant benefits to being able to draw on Alfa Laval’s local service network and expert resources to get response to any technical questions that arise – as they inevitably will.

What does our customer say

According to Paul Doherty, Watercare Service Project Engineer at the Mangere WWTP and responsible for the solids stream upgrade,

the equipment has exceeded his expectations regarding treatment capacity and reliability.

there have been significant benefits to being able to draw on Alfa Laval’s local service network and expert resources to get response to any technical questions that arise – as they inevitably will.