Aalborg OL

The Aalborg OL is a large capacity oil-fired steam boiler. It is designed to provide optimal combustion conditions.

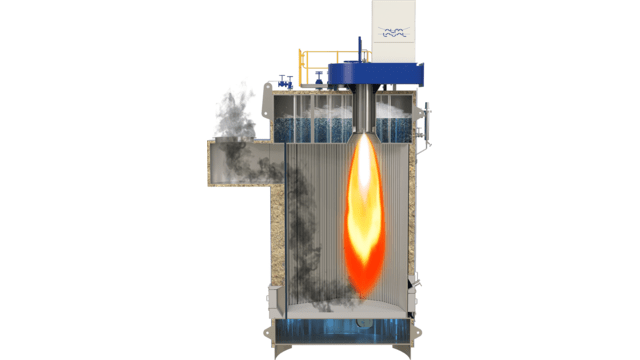

Aalborg OL is intended for steam or hot water production, the oil- or gas-fired Aalborg OL (formerly MISSION OL) is supplied as a vertical, two-drum cylindrical boiler.

Its furnace, which is built with membrane walls and contains only little refractory material, is shaped to provide optimal combustion conditions.

Features and benefits of the Aalborg OL product

- Two-drum cylindrical water tube boiler

- Standard preassembled modules

- Innovative PLC-based control system

- Top-fired compact design

- Membrane wall design

- Made of mild carbon steel with elevated temperature properties

- Integrated steam atomizing burner

- Refractory is reduced to a protective layer at the bottom of the furnace

How it works

Top-fired and available in two different design pressures, the Aalborg OL is a vertical, two-drum cylindrical boiler. Straight tubes connect the water and steam drums directly, which ensures safe circulation with no risk of overheating and subsequent tube burnout.

The furnace is built with membrane walls, which are constructed from gastight polygonal panels that make it resistant to gas pulsations. Containing only a minimum of refractory material, it is shaped to provide optimal combustion conditions. The convection section consists of straight pin tubes with bent pins, which provide a high coefficient of heat transfer and ensure low pressure loss. Circulation is promoted by downcomers placed outside the membrane walls.

Steam and hot water production

- Design pressure: 9 or 18 bar(g)

- Capacity: 12,500–45,000 kg/h

- Burner recommendation: Alfa Laval Aalborg KBSD pressure-atomizing burner

Ship types

- VLCC tanker

- Suezmax tanker

- Aframax tanker

- Panamax tanker

- FPS unit