LeviMag UltraPure

Alfa Laval magnetic mixers maximize product yield in biotech, pharmaceutical and other aseptic applications with high hygienic demands. The unique levitating impeller design enables effective mixing right down to the last drop.

Maximum yield magnetic mixer

Alfa Laval magnetic mixers represent a breakthrough in mixing technology. The unique levitating impeller design allows the mixer to operate under dry conditions, making it possible to mix down to the last drop. This minimizes product loss, which may positively impact process economy. In biotech and pharmaceutical applications, where product is particularly valuable, these savings can pay back the initial cost of investment, including the mixer, installation, testing and revalidation, in just a matter of weeks.

Wide range of speeds

The levitating impeller design eliminates friction, making it possible to mix at speeds ranging from 10 to 600 rpm. The 4 sizes of mixers enables the flexibility to handle a wide range of fluid types and mixing duties, such as high intensity mixing and gentle product mixing.

Gentle product treatment

The unique eight-wing design of the impeller delivers efficient mixing at very low speeds. This ensures the most gentle product treatment possible with very low share forces.

Unparalleled hygiene, optimized operation

The magnetic mixer range offers unparalleled hygiene due to its levitating impeller design. The mixer rotates at very low rpm during cleaning, resulting in a more effecient cleaning. Because there are no entrapment areas, the magnetic mixer can be completely drained of product and cleaning solutions. The open design also ensures full coverage by the cleaning solution and contributes to efficient removal of product residues. The lack of friction also minimizes product contamination from wear particles.

Fully documented

Alfa Laval MM UltraPure magnetic mixers are backed by the assurance of our comprehensive documentation package, securing safe material and full traceability.

Product Benefits

- Maximum yield magnetic mixer

- Minimizes product loss

- Wide range of speeds

Product catalogue

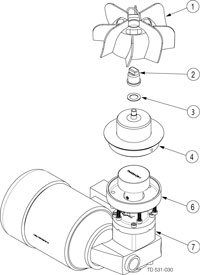

How it works

A radial turbine installed inside the tank is rotated via the torque from a magnetic coupling. This creates mixing of the fluid inside the tank. The patented levitated design of the Alfa Laval LeviMag UltraPure impeller makes the mixer fully drainable and able to run dry; it can therefore mix to the last drop, securing maximum yield.

The unique design of the Alfa Laval magnetic coupling ensures the levitation of the impeller at all times. This enables the complete drainability of process fluids and the free flow of CIP liquid and steam around all parts of the mixer, thereby ensuring thorough cleaning. Impeller levitation also eliminates axial wear.

The unique design of the Alfa Laval magnetic coupling ensures the levitation of the impeller at all times. This enables the complete drainability of process fluids and the free flow of CIP liquid and steam around all parts of the mixer, thereby ensuring thorough cleaning. Impeller levitation also eliminates axial wear.

The eight-winged impeller design ensures balanced operation at very low speeds and minimize wear of the bearings (2). Male bearings can easily be replaced with a bearing tool.