Foodec

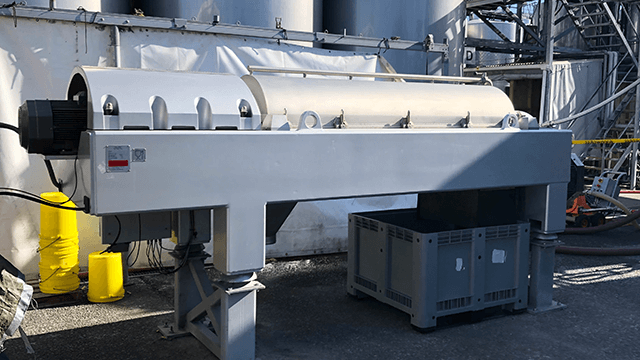

Alfa Laval Foodec decanter centrifuges are ideal for industries where delicate food and beverage products are processed – and where easy cleaning is crucial.

Centrifugal separator with unparalleled efficiency and easy cleaning

- Higher juice extraction yield, drier cake and clearer liquid

- Easy and fast cleaning with CIP thanks to AL cleaning technology and software

- High operational flexibility to adapt to different processes or fruits

- Wide range of available decanter size all with premium G-Force level

Alfa Laval Foodec is designed to minimize separation costs while delivering a high quality end product. The design is ideal for the manufacture of beverages and viscous foods. The drive system offers much lower power consumption than alternative technologies. The innovative control system reduces operating costs while giving you better control over the separation process.

Highlighted applications:

- Winery

- Brewery

- Fruit juice

- Milk

- Soy protein

- Plant-based beverages such as oat, almond and rice drinks

- Tomato

How it works

How does the Foodec decanter centrifuge work

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. A stationary inlet tube introduces the product into the bowl, and a distributor gradually accelerates it. Centrifugal forces separate solids from the liquid. The solids are collected and compacted on the bowl wall.

A conveyor rotates inside the bowl at a slightly different speed. This transports the settled solids on the bowl wall towards the conical end. Foodec's design increases hydraulic pressure inside the drum to improve flow through a narrow opening. The compacted and dewatered solids leave the bowl via discharge openings at the smaller diameter of the conical end. Separation takes place in the entire length of the cylindrical part of the bowl, and the clarified liquid leaves through a paring disc (internal centripetal pump).

All wetted parts in Foodec decanter centrifuges for the food industry are made with stainless steel. The control system is equipped with a graphic user interface and multiple communication options.

TrueStainless™

Designed for long-lasting and unmatched hygiene.

TrueStainlessTM ensures solid stainless steel is used for the frame and other key parts that may be in contact with corrosive atmospheres, leading to optimal hygiene and longer equipment life.

Accelerate your grape juice extraction

Juice extraction is an essential process in winemaking. The traditional ways to do this are with different kinds of presses and then filters or settling tanks, in which gravity makes particles, sediment and solids gradually fall to the bottom. Now, the Foodec centrifugal decanter offers a gentle yet effective way to extract grape juice faster. Download the application brochure for wineries.

Upgrade your Foodec with SaniRibs® transportation aid

Intended for separation tasks in the food industry, the SaniRibs design eliminates crevices under traditional spot-welded transportation aids and minimizes the risk of bacterial growth, offering a unique combination of excellent hygiene and outstanding separation performance

Choose a supplier with local service and support

You can trust Alfa Laval service technicians to repair your decanter centrifuges. With a major Decanter service centre in Hamilton and New Zealand-wide field service, Alfa Laval helps you keep your equipment performing at peak and minimize the risk of unscheduled production stops.

Maximize operating reliability with Alfa Laval IoT Services

Alfa Laval’s IoT Services is a range of digital services that maximizes operating reliability and uptime in food & beverage processing plants.