2020-12-10 Product news

How the COVID situation will accelerate technology innovation in NZ wineries

With second waves affecting many major wine growing regions around the world, it seems highly unlikely that New Zealand will relax border and quarantine rules anytime soon. Wineries large and small are expecting severe skill shortages – both manual and highly skilled labour – and are looking at ways to prepare for a successful harvest and processing season.

We speak with Roger Johnson, National Sales Manager, Food and Water Division, Alfa Laval New Zealand, about the impact on the 2021 vintage and which technology areas offer the greatest potential for productivity gains.

Why is the COVID situation affecting NZ wineries?

Winemaking is an industrialised process that also involves skilled craftsmanship and art. This means not only seasonal labour, but the NZ market at least historically draws on a global skill base from the other major wine growing regions such as North and South America, South Africa and Europe. With the current travel restrictions in place, it’s harder to bring technical specialists to New Zealand for the next harvest and that affects wineries across the board.

What are the technologies that vineyards are looking at for productivity and automation?

I’ve seen media commentary looking at machine harvesting as an obvious area, especially as it’s difficult to justify two weeks of quarantine for a six-week harvest season for fruit pickers (e.g. Rural News).

But it’s not the only technology that local winemakers should be looking at. Efficiency and productivity gains can be found in many other areas of harvest and vintage.

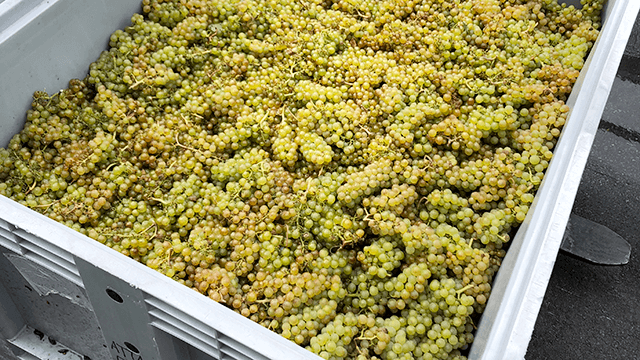

Take for example grape juice extraction. Most local wineries are still using soft press technology. Using a press to extract the juice is not only more time consuming but a multi-step process with extensive labour requirements. That’s why vineyards in other parts of the world have invested in decanter technologies which involves fewer resources and steps with better results in juice clarity.

Why is it a good time to invest in new technologies?

Vineyards are under a lot of pressure at the moment but as they say, every challenge is an opportunity. I think we will look back and recognise that the unique situation with the pandemic has been a catalyst for innovation in the industry. In contrast to many other wine-producing regions, New Zealand has a lot of potential left for growth, due to our ideal climatic conditions and proximity to Asia.

My advice to local winemakers would be to do their research on new technologies and equipment available to the industry today. For example, read up on the international studies that compare soft press with decanter technology for grape juice extraction and see how the results stack up.

The other recommendation is to go with a technology partner with a strong local market and service presence. The travel restrictions apply also to technical specialists, so it’s never been more important to have people on the ground. Alfa Laval has a major service centre in Hamilton and offers field service support by some of the industry’s most experienced technicians across the North and South Islands.

What else is Alfa Laval doing with wineries?

Alfa Laval covers the entire winemaking process with a comprehensive range of technologies, solutions and equipment. We work with wineries around the world drawing on our leading product ranges in the areas of heat transfer, separation and fluid handling. Our commitment is to help customers achieve maximum flexibility, scalability and reliability, sustainability and uptime. Our product portfolio is extensive.

Some of the other key technologies that will give NZ wineries an advantage include the Foodec decanter, our range of high-speed centrifugal Clara separators, as well as heat exchangers, wastewater treatment solutions and membrane filtration systems. Together with our NZ distributors we also supply everything wineries would need for hygienic fluid handling and tank cleaning.

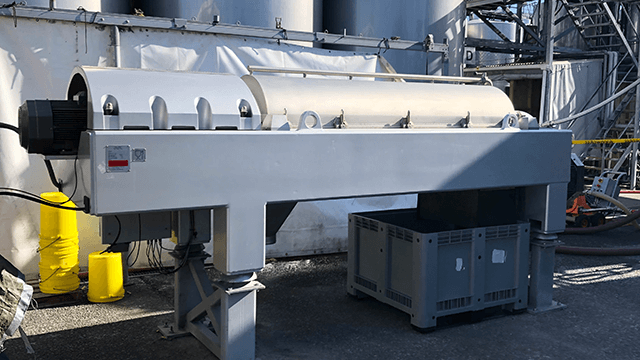

The Alfa Laval Foodec 500 is a fast yet gentle centrifugal decanter that replaces traditional soft press filters for grape juice extraction.

Meet the expert

Roger Johnson

National Manager for Food & Water

Alfa Laval New Zealand

Roger Johnson is Alfa Laval’s National Manager for Food & Water in New Zealand, helping customers optimise food and beverage production with sustainable solutions that save cost, add value and bring environmental benefits. Roger has more than 15 years’ experience as a process engineer and industry expert. His career spans Alfa Laval’s extensive product portfolio of thermal, separation and hygienic fluid handling portfolio with multiple senior engineering and sales roles. For the past seven years, he has been focusing on the food and beverage industry, working closely with winery and brewery customers around NZ on solving problems and improving production processes.